Products Description Tel:0917-3664600

Material composition: Micro Nickel foil is made of pure nickel metal with a minimum purity level of 99.5%. It has a high melting point and corrosion resistance, making it ideal for use in harsh environments.

Product features:

Micro Nickel foil has excellent electrical conductivity, high thermal conductivity, and good mechanical properties. It is also resistant to corrosion, oxidation, and high-temperature environments.

Thickness: The thickness of Micro Nickel foil varies from 0.005mm to 0.1mm, depending on the requirements of the specific application. It is available in different thicknesses to suit different applications.

Width and length: Micro Nickel foil is available in different widths and lengths, ranging from a few millimeters to several meters. This makes it easy to use in various applications, including electrical contacts, battery components, and electronic shielding.

Specification Tel:0917-3664600

| Grade | Ni201 Ni200 |

| Size | Thick 0.005 to 0.1mmx Max wide 1300mm |

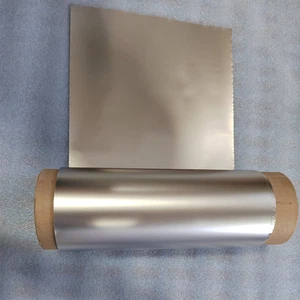

| Surface | smooth and shiny surface |

| Standards | ASTMB162 |

Factory Tour Tel:0917-3664600

How is micro nickel foil is made out? Tel:0917-3664600

Nickel foil that has been electrodeposited through the electroplating process is known as micro ED Nickel foil. The following steps are involved in the production of Micro ED Nickel foil:

Preparation of the Nickel Plating Solution: The first step is to make the nickel plating solution. This mixture contains nickel salt, which has been dissolved in water, as well as a number of additives, including surfactants and accelerators.

A thin layer of nickel is electrodeposited on a substrate, usually made of copper or stainless steel after the nickel-plating solution has been added to an electroplating bath. The voltage and current density in the electroplating bath are adjusted to control the thickness of the nickel layer.

After that, the electrodeposited nickel layer is put through an annealing process, which involves heating the metal to a specific temperature and holding it there for a predetermined amount of time. This method aids in enhancing the nickel layer's ductility and toughness.

Cleaning and cutting: Any surface impurities or contaminants are then removed from the nickel layer after it has been annealed. Following cleaning, a cutting machine is used to cut the nickel layer to the required size and shape.

Testing the quality of the Micro ED Nickel foil is the last step. To make sure the product complies with the specifications, it is necessary to check its thickness, surface quality, and other mechanical properties.

Applications of micro nickel foil Tel:0917-3664600

Micro Nickel foil is used in a wide range of industries, including the production of batteries, electronics, telecommunications, and aerospace. It is used to make components for thermal management, shielding, current collectors, and electrical contacts.

Battery production: Electrodeposited pure nickel foil is widely used in battery production, especially in the manufacture of lithium-ion batteries. It is used as a current collector, which helps to improve the battery's performance and durability.

Electronics: Micro Nickel foil is used in the production of electronic components such as capacitors, resistors, and sensors. It is also used as a shielding material to protect electronic devices from electromagnetic interference.

Aerospace: Nickel foil is used in the aerospace industry to manufacture lightweight parts such as rocket nozzles, satellite components, and aircraft engine parts.

Medical devices: Micro Nickel foil is used in the production of medical devices such as pacemakers, surgical instruments, and implants. It is biocompatible and corrosion-resistant, making it suitable for use in the human body.

Automotive: Electrodeposited Nickel foil is used in the automotive industry to manufacture parts such as fuel injectors, catalytic converters, and exhaust systems. It is resistant to corrosion and high temperatures, making it ideal for use in harsh environments.

Decorative applications: Nickel foil is used in decorative applications such as jewelry, watches, and silverware. It has a shiny and lustrous appearance, making it a popular choice for decorative purposes.

Packing And Shipping Tel:0917-3664600

Packaging: Nickel foil is usually packaged in rolls or sheets with protective layers to prevent damage during transportation and storage.

Micro Nickel foil is a versatile material with various applications in different industries. It's excellent properties and customizable dimensions make it a popular choice for many applications.

Other related titanium foil, titanium strips.

Hot Tags: astmb162 high purity micro nickel foil, China, suppliers, manufacturers, factory, customized, wholesale, bulk, low price, for sale, in stock, buy discount, made in China